About Us

Breakthrough

Anping County Shengxin Metal Products Co., Ltd

INTRODUCTION

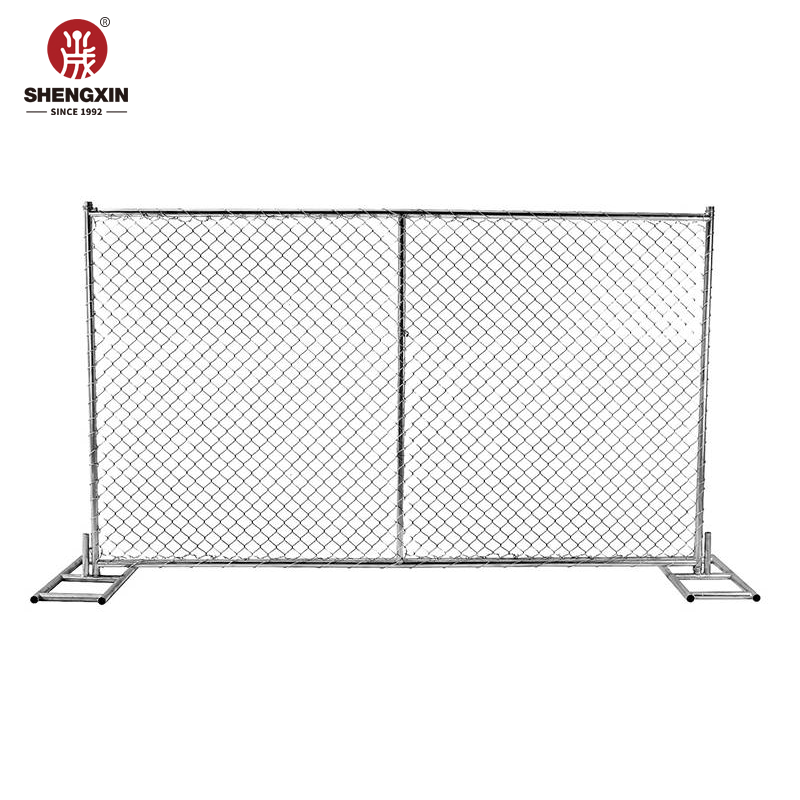

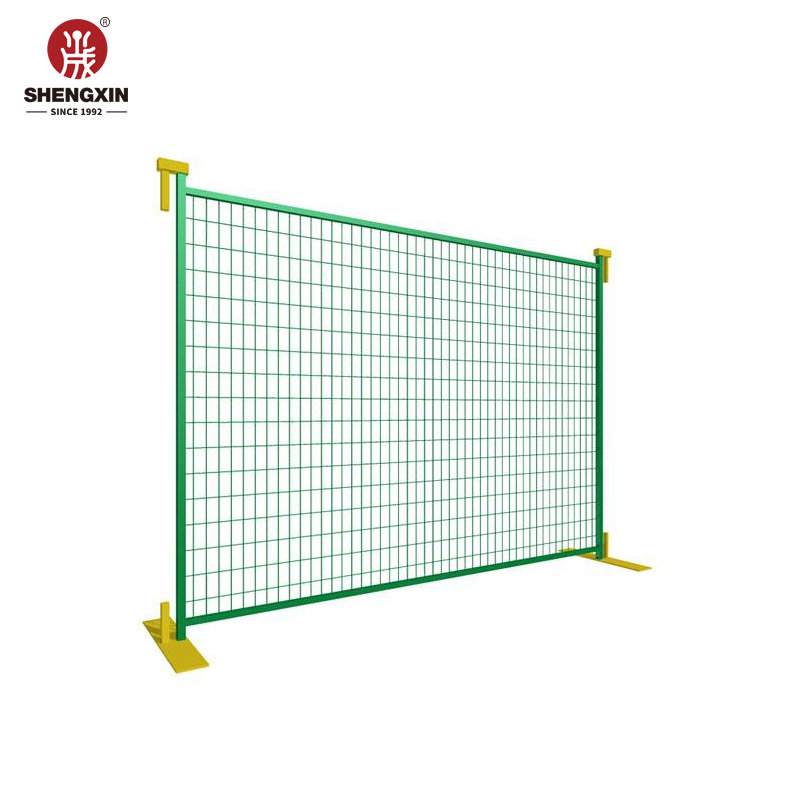

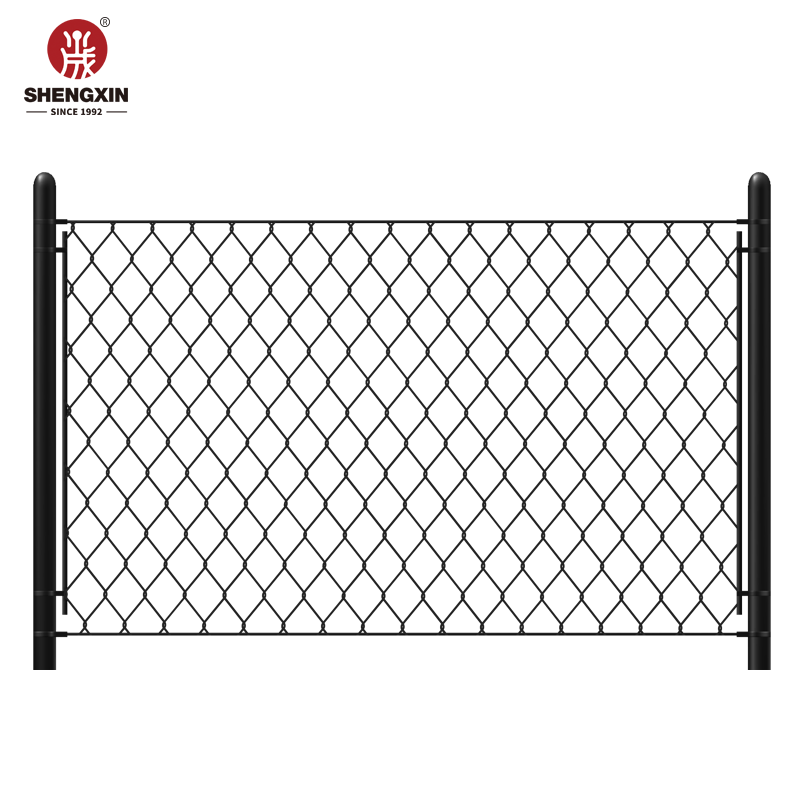

SHENGXIN FENCE is a global leader in designing and manufacturing top-guality fencing and gate solutions. Since our inception in 1992, we've leveraget over 32 Years of expertise to export our products worldwide for industrial and commercial applications.Our product range covers wire mesh fence, chain link fence, and temporary fence, along with anti climb fence and various gate options. Our skiled eam offers comorehensive support,from design to producted, The Perfect inspection department and personnel ensure that every fence shiped from the factory is of high quality.

SHENGXIN FENCE is renowned for quality workmanship and eficiency, consistently meeting industry standards. We prioritize our customers with the principle of "Customer First, Everwhere" providing high-guality. affordable Fence. Choose SHENGXIN FENCE for trusted protection. Your trust is well-placed!

-

-Metal Fence Factory in 1992

-

-+Patent and Certificates

-

-+Export to 130+ Countries and Regions

-

-㎡Factory Area

Factory

Innovation

Main Products

Innovation

News

Service First

-

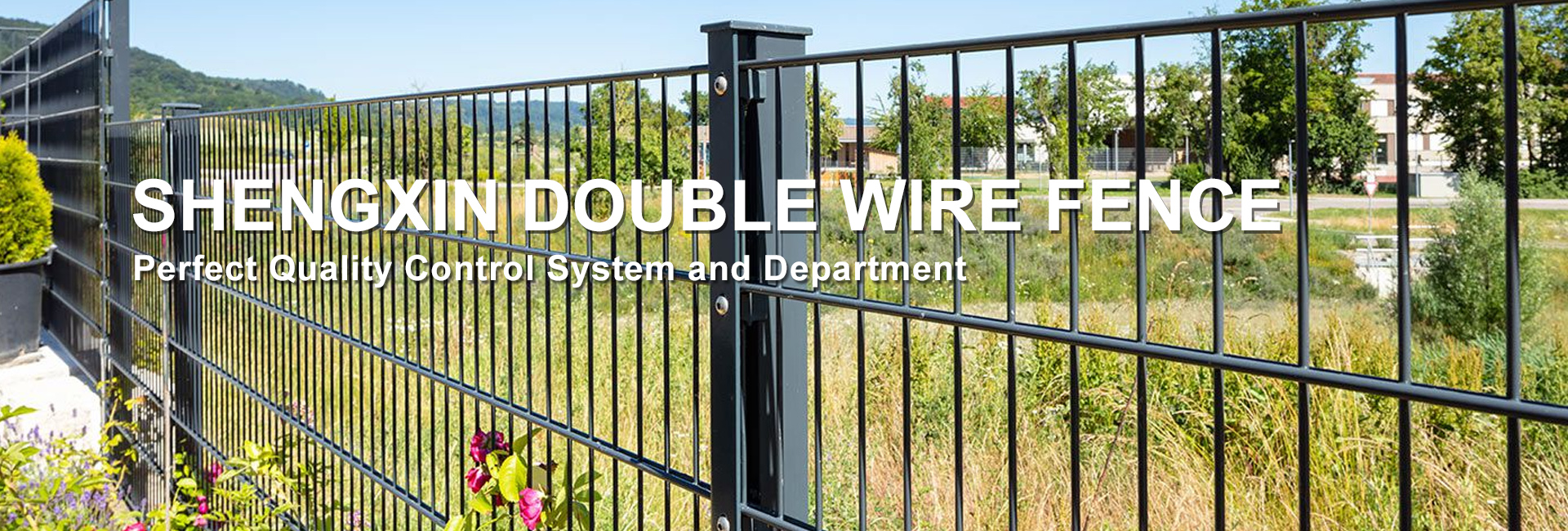

Enhancing Security with Innovative 3D Wire Fence Solutions

Enhancing Security with Innovative 3D Wire Fence Solutions

-

DIY Compost Bin anti climb fence

Connect two frames with two door hinges, then put two hook-and-eye gate latches on the other ends. Repeat this step for the remaining two frames. Stand the frames to form a square and latch the sections together.